Phenolic Foam Insulation Board

Model No.︰-

Brand Name︰GOOT

Country of Origin︰China

Unit Price︰CNY ¥ 1000 / pc

Minimum Order︰1 pc

Product Description

Detailed introduction to Phenolic Foam Insulation Board:

henolic Foam Insulation Board in Building Application:

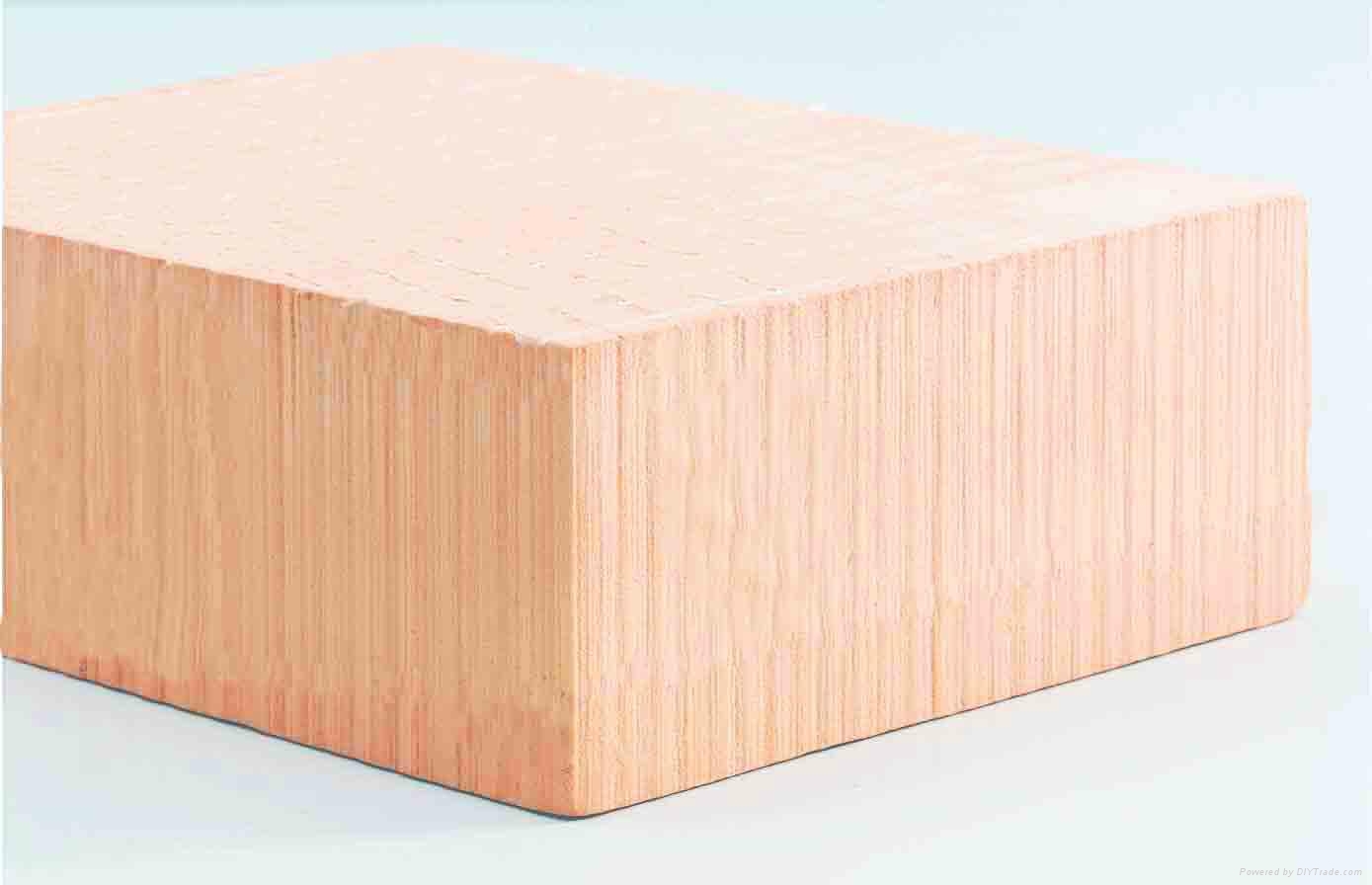

Closed cell phenolic foam is used extensively in the building industry for a number of application areas including roofing, cavity board, external wall board, plaster board dry linings systems, floor insulation and as sarking board. Phenolic foams offer significant advantages over other insulation materials which are summarised below. A range of phenolic foam boards is available to suit most new buildings or refurbishment applications.

Flexible-faced phenolic foam boards used in the building industry are typically manufactured in the continuous lamination process. This involves spraying a mixture of phenolic resin, catalyst and blowing agent onto a moving facing. A top facing is then introduced and the product then goes through a heated conveyor press and heated ovens and is then cut to the required size. Phenolic foam products with Agrément certification are available for roofing, cavity board, floor board, dry lining, external wall board and sarking board.

ADVANTAGES

Space saving: the exceptionally low thermal conductivity of closed cell phenolic foam boards means that appropriate insulation efficiency can be achieved with the thinnest possible material. This can be a significant advantage in building regulations, for example, in plaster board dry lining systems where internal room space is maximised and in cavity wall applications where the building envelope thickness is minimised.

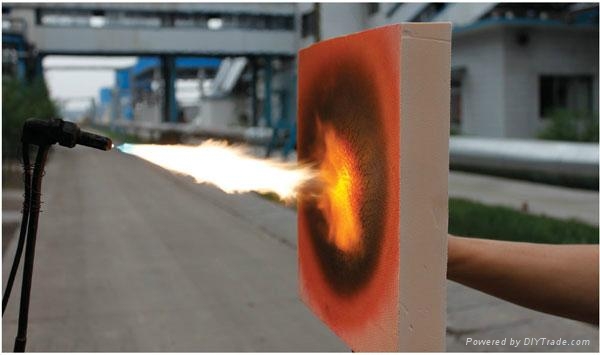

Class O fire rating in accordance with the Building Regulations 1992 Edition, Approved Document B,

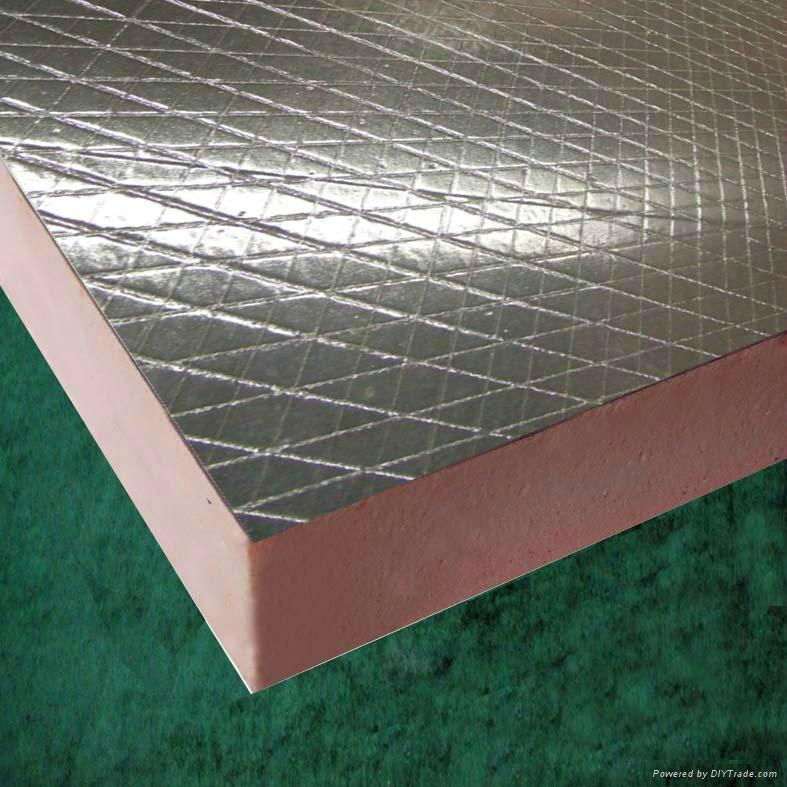

Factory applied Class O rated aluminium foil or glass tissue facings are available

Exceptionally low smoke emission - less than 5% when tested in accordance with BS 5111 : Part 1

Excellent moisture resistance as a result of low water vapour permeability and 90% closed cell structure

Non fibrous: this is particularly relevant for use in hospitals, food preparation areas and breweries

Manufactured under ISO 9002 Quality Management System

Payment Terms︰ TT

Product Image